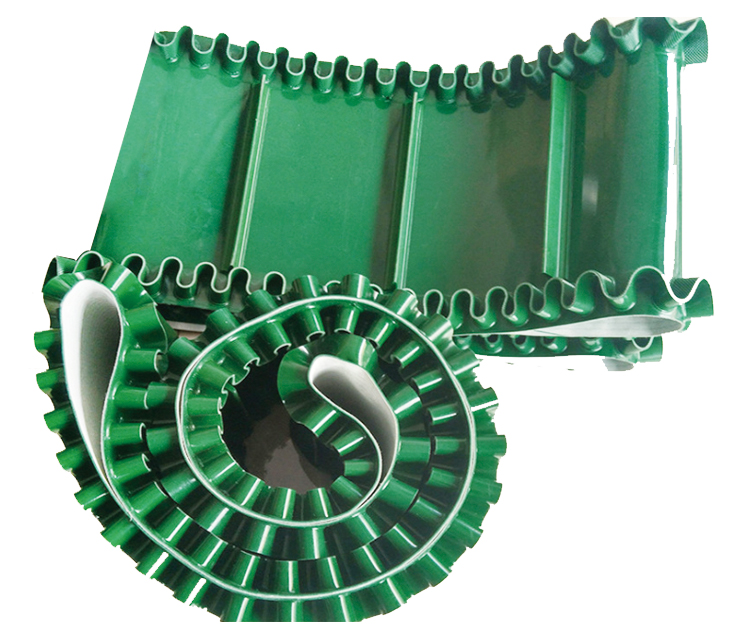

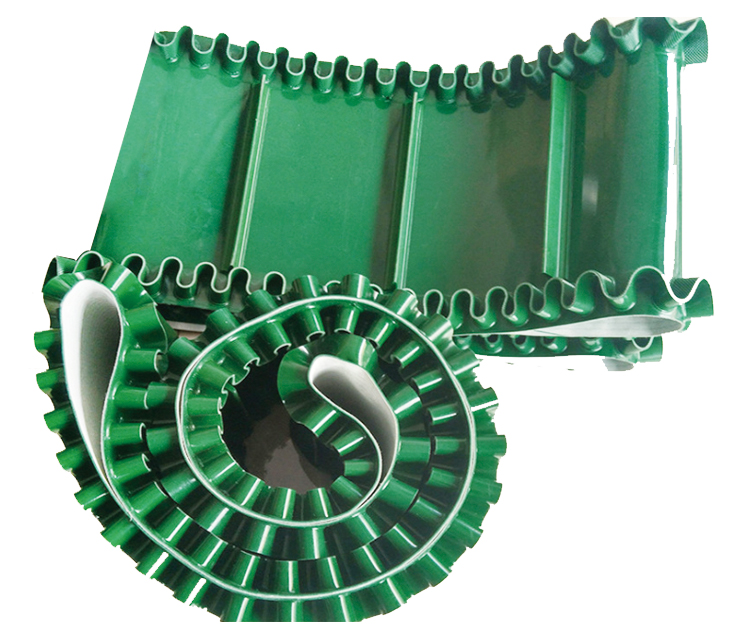

大倾角输送带的主要部件是滚子部件,因此产品在选型时必须特别注意该部件的设计。接下来我们来看看大倾角带式输送机辊筒的选择技巧。

Roller parts are the main parts of belt conveyor with large inclination, so the design of this part must be paid special attention to in the selection of products. Next, let's look at the selection techniques of rollers for belt conveyors with large inclination.

1. 滚筒壁厚和轴径的选择:输送物料的重量均匀地分布在接触的滚筒上,计算每个滚筒所需的承载能力,从而确定滚筒壁厚和轴径;

1. Choice of the thickness and diameter of the drum: The weight of the conveying material is evenly distributed on the contact drum, and the bearing capacity of each drum is calculated to determine the thickness and diameter of the drum.

2. 滚筒长度选择:对于不同宽度的货物,应选择合适宽度的滚筒。输送物料一般在50mm左右。

2. Drum length selection: For goods with different widths, the appropriate width of the drum should be selected. The conveying material is usually about 50 mm.

滚筒材料与表面处理:根据运输环境的不同,确定滚筒材料与表面处理。

Drum material and surface treatment: According to the different transportation environment, determine the material and surface treatment of the drum.

说了这么多关于大倾角皮带机的知识,也不知道我们是否了解它。如果您有任何问题,请与我们的工作人员联系。

Having said so much about the high-angle belt conveyor, I don't know whether we know it or not. If you have any questions, please contact our staff.

在高倾角带式输送机的安装和铺设过程中,由于设备的不均匀层巷道,在不同的位置会有凹凸,所以整体的承载带应集中在一些设备的懒汉,当材料传输太重,很容易造成损害的懒汉设备,影响顺利生产。

In the process of installation and laying of high inclined belt conveyor, because of the uneven roadway of equipment, there will be concave and convex in different locations, so the whole bearing belt should be concentrated on the lazy men of some equipment. When the material transmission is too heavy, it is easy to cause damage to the lazy men equipment, affecting the smooth production.

因此,合理调整的大倾角带式输送机纵向坡度,以缓解的凹凸部分底座,凸曲线状态,应力集中的位置可以增加套轴承滚子的重托,以确保整个皮带和辊每组可以得到良好的接触,在一定程度上,消除应力集中,保证大倾角带式输送机纵向坡度合理,倒带运行。

Therefore, the reasonable adjustment of the longitudinal gradient of the belt conveyor with large inclination can alleviate the concave-convex part of the base, the convex curve state, and the position of stress concentration can increase the heavy support of the sleeve bearing roller, so as to ensure that the whole belt and the rollers can get good contact, to a certain extent, eliminate the stress concentration, ensure the reasonable longitudinal gradient of the belt conveyor with large inclination and the operation of the inverted belt.

For more information, click on the official website: https://www.huafengxiangsu.com.