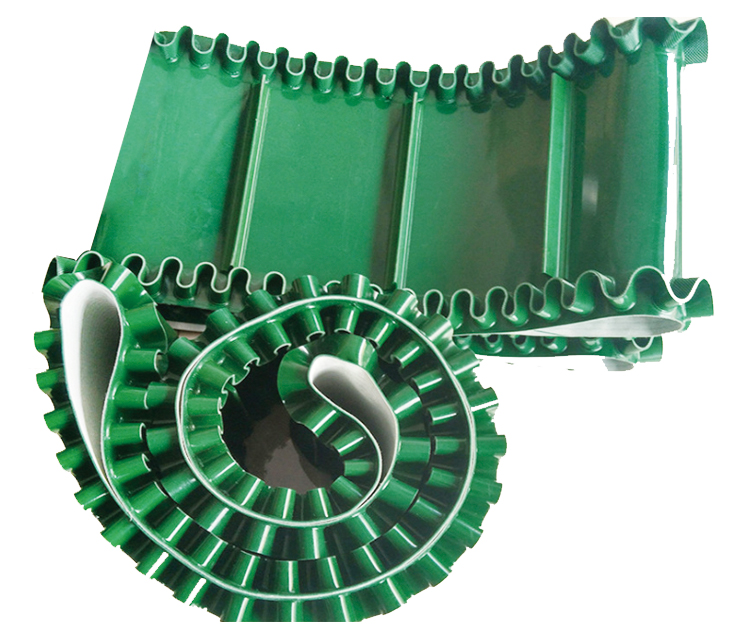

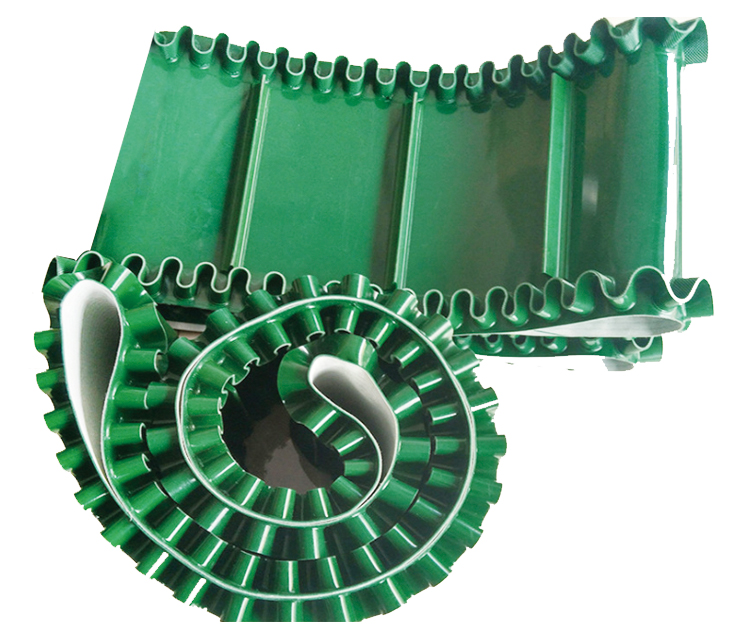

传送带在应用程序的整个过程和每个部分的输送机摩擦,摩擦在正常范围内,以确保传送带的使用,但是如果传送带和其他部分的摩擦增加,将造成损害的传送带,下来很长一段时间将导致传送带早期报废,使用期间不高。那么输送带在整个操作过程中会与这些部件产生摩擦吗?下面就带式输送机的生产厂家进行深入分析。

The conveyor belt is in friction with each part of the conveyor during the whole process of the application. The friction is within the normal range to ensure the use of the conveyor belt. However, if the friction between the conveyor belt and other parts increases, it will cause damage to the conveyor belt, which will lead to early scrapping of the conveyor belt for a long time, and the use period is not high. Will the conveyor belt produce friction with these parts in the whole operation process? The following is an in-depth analysis of the belt conveyor manufacturers.

1. 声卡架与传送带之间的摩擦。有时,由于输送带在生产、安装和使用中存在的缺陷,输送带会偏离方向。

1. Friction between sound card rack and conveyor belt. Sometimes, because of the defects in the production, installation and use of the conveyor belt, the conveyor belt will deviate from the direction.

2. 通道分离器与输送带之间的摩擦。分离器对输送带的损坏就是这样一种独特的损坏。

2. Friction between channel separator and conveyor belt. The damage of separator to conveyor belt is such a unique damage.

3.缓冲托辊之间的摩擦和传送带,传送带的下盖胶也深受定心缓冲托辊的摩擦力和远期扩展槽空转,这通常是在槽之间的连接部分受损惰辊和突出的输送机的一部分。

3. The friction between the buffer idlers and the conveyor belt, the lower cover rubber of the conveyor belt are also deeply affected by the friction of the centering buffer idlers and the idling of the long-term expansion slot, which is usually a part of the damaged idler roller and the protruding conveyor in the connecting part between the slots.

4、清洁工和传送带摩擦,清洁工造成损害的传送带是对称的,但随着硬厚钢板作为一个干净的盘子,如果使用不当,也会除了浪费硫化橡胶钻出来,当清洁工,指出,传送带之间的土将传送带长度上深深的伤痕。

4. When the cleaner rubs against the conveyor belt, the conveyor belt damaged by the cleaner is symmetrical, but with the hard steel plate as a clean plate, if it is not used properly, it will also waste vulcanized rubber to drill out. When the cleaner points out that the soil between the conveyor belts will cause deep scars on the length of the conveyor belt.

以上是输送带在整个运行过程中产生摩擦的关键位置。希望您能根据本文的详细介绍有一定的把握。在应用中,需要保证输送带与各个位置之间的摩擦满足要求,从而保证输送带的工作效率和使用寿命,从而降低公司的产品成本。请关注我们的网站,以获取更多关于传送带的信息。

The above is the key position of friction in the whole operation process of conveyor belt. I hope you can have some assurance according to the detailed introduction of this article. In the application, it is necessary to ensure that the friction between the conveyor belt and each position meets the requirements, so as to ensure the working efficiency and service life of the conveyor belt, so as to reduce the product cost of the company. Please follow our website for more information about the conveyor belt.