1、温度:食品加工输送线,不同区段有不同的温度要求,前端原料一般采用普通食品级输送带,高温干燥段,用耐高温食品级网络链或特氟龙输送带,干燥后冷却段采用特氟龙或耐高温食品级输送带。

1. Temperature: different sections of the food processing conveyor line have different temperature requirements. Common food grade conveyor belt is generally used for front-end raw materials, high temperature drying section, high temperature food grade network chain or Teflon conveyor belt is used, and Teflon or high temperature food grade conveyor belt is used for cooling section after drying.

2、辊直径:不同厚度的带对应于不同的辊,在设计过程中考虑带本身的转弯半径,辊的直径应大于更小直径的带要求,所以带不会导致磨损和老化设备的设计问题。提高皮带的使用寿命。

2. Roll diameter: different thickness of the belt corresponds to different rolls. In the design process, the turning radius of the belt itself should be considered. The diameter of the roll should be larger than that of the belt with smaller diameter, so the belt will not lead to wear and aging. Improve the service life of the belt.

3、物料重量:每个食品级输送带都有固定的线层来承受物料重量。在设计过程中,应考虑输送带的承载能力,以避免在设计之初输送带的过载。

3. Material weight: each food grade conveyor belt has a fixed line layer to bear the material weight. In the design process, the bearing capacity of the conveyor belt should be considered to avoid the overload of the conveyor belt at the beginning of the design.

4、耐油性:食品输送行业对输送带的耐油性有很多要求,如月饼、面包、沙七马、海带等食品产品都是油性的,且未加工成型的菌体也不是油性的,一般的食品级输送带就可以满足。

4. Oil resistance: the food transportation industry has many requirements for the oil resistance of conveyor belt, such as moon cake, bread, ShaQima, kelp and other food products are oily, and the unprocessed bacteria are not oily, the general food grade conveyor belt can meet.

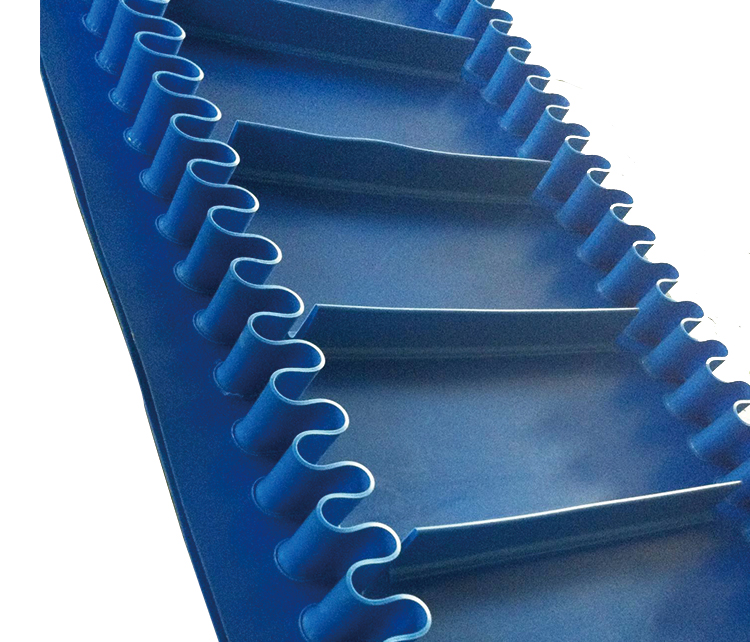

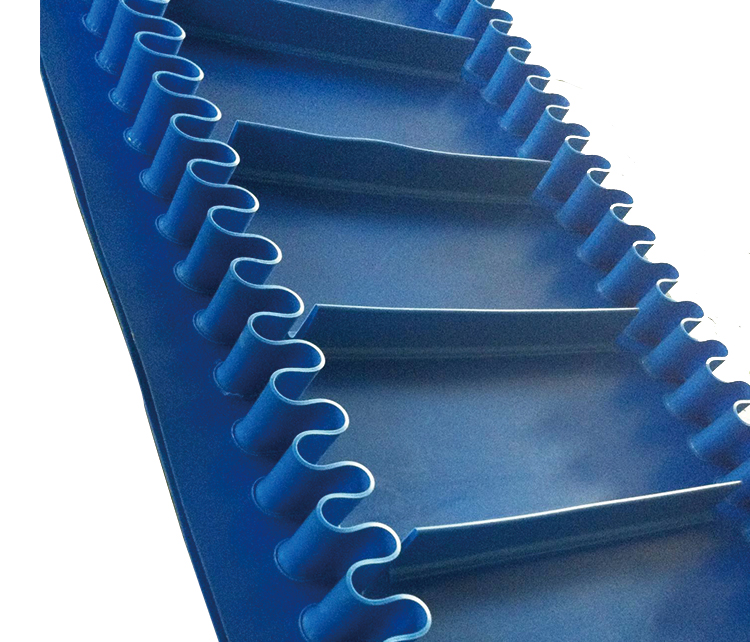

5、食品级输送带的颜色:白色传送带通常用于直接接触食品,避免皮带的颜色对食品污染,绿色传送带一般用于食品的包装输送机部分,蓝色传送带一般用于出口设备,有一定的杀菌效果。

5. Color of food grade conveyor belt: white conveyor belt is usually used for direct contact with food to avoid food pollution caused by the color of the belt, green conveyor belt is generally used for food packaging conveyor, and blue conveyor belt is generally used for export equipment, which has certain sterilization effect.