现保送带产业中,契合食品级的保送带材质有PU(聚氨酯)、PE(聚乙烯)、PVC、SIR(硅橡胶)、PTFE(特氟龙)几种。

In the present delivery belt industry, the food-grade delivery belt materials are PU (polyurethane), PE (polyethylene), PVC, SIR (silicone rubber), PTFE (Teflon).

PU(聚氨酯):通式 -[-O-CONH-]n-

PU (polyurethane): general formula - [-O-CONH-]n-

聚氨酯是聚氨基甲酸酯的简称,是指主链上含有反复聚氨甲酸酯基团的大分子化合物统称,具有耐磨耐温、无污染、无毒无味、抗多种酸碱(PH值在5-9之间)和有机溶剂的腐蚀。

Polyurethane is the abbreviation of polyurethane, which refers to the macromolecule compounds containing repeated polyurethane groups in the main chain. It has the characteristics of wear resistance, temperature resistance, pollution-free, non-toxic and odorless, anti-corrosion of various acids and bases (PH value between 5-9) and organic solvents.

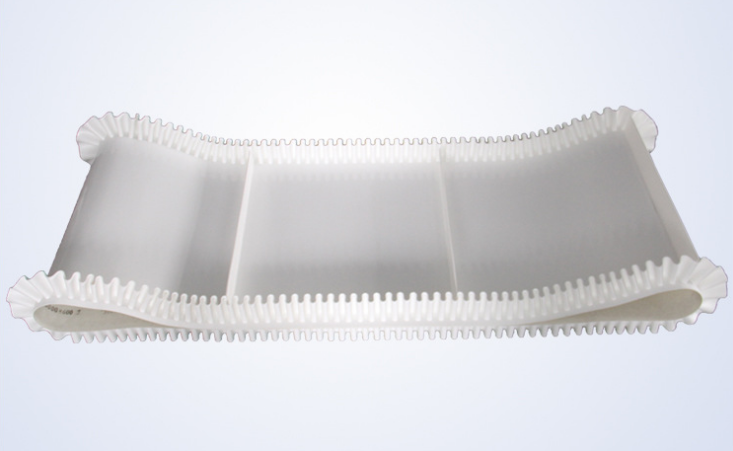

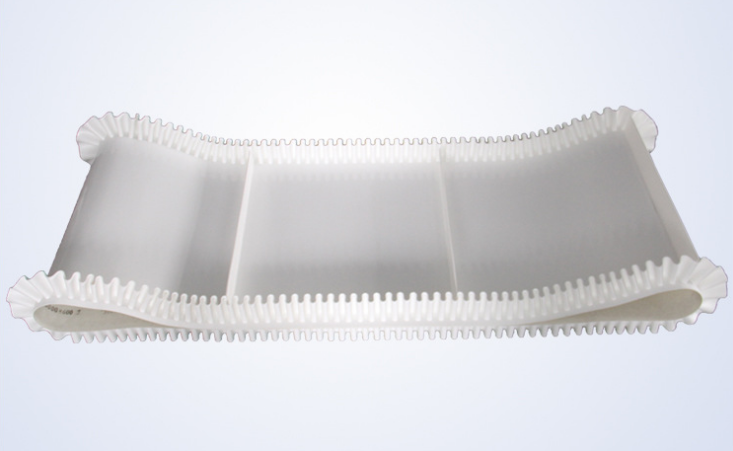

PU食品级保送带,运用聚氨酯作为原资料,具有横向稳定性的聚酯织物作为承载骨架,契合FDA食品级规范,已在国际食操行业通用。

PU food-grade delivery belt, using polyurethane as raw material, polyester fabric with transverse stability as load-bearing skeleton, conforms to FDA food-grade specifications, has been widely used in the international food and gymnastics industry.

PE(聚烯氢):通式nCH2=CH2→—[CH2—CH2]n—

PE (polyolefin hydrogen): general formula nCH2=CH2-[CH2-CH2]n-

聚烯氢是烯氢聚合而成的聚合物,具有稳定的化学性能,室温下可耐多种化学物质的腐蚀(除硝酸、硫酸外),无毒无味,运用温度在-70℃~+150℃。

Polyolefin hydrogen is a polymer synthesized from olefin hydrogen. It has stable chemical properties. It can resist the corrosion of many chemical substances (except nitric acid and sulfuric acid) at room temperature. It is non-toxic and tasteless, and its application temperature is - 70 ~150 ~C.

PE食品级保送带,运用聚烯氢作为原资料,具有横向稳定性的涤纶短纤织物作为承载骨架,契合FDA食品级规范,高温熄灭无毒,合适烟草行业和食操行业的保送。

PE food-grade delivery belt, using polyolefin hydrogen as raw material, polyester staple fabric with transverse stability as load-bearing framework, conforms to FDA food-grade specifications, high temperature extinguishing non-toxic, suitable for tobacco industry and food and gymnastics industry delivery.

PVC(聚氯乙烯):通式[ ―CH2 ―CHCl― ]n

PVC (polyvinyl chloride): General formula [- CH2 - CHCl - n]

聚氯乙烯是氯乙烯的聚合物,具有稳定的物理化学性质,能耐多种酸碱。

Polyvinyl chloride (PVC) is a polymer of vinyl chloride, which has stable physical and chemical properties and can resist various acids and bases.

PVC食品级保送带,运用聚氯乙烯作为原资料,具有横向稳定性的聚酯织物作为承载骨架,契合卫生指标,具有无毒无味、不易变形、轻巧耐用等特性。

PVC food-grade delivery belt uses polyvinyl chloride as raw material, polyester fabric with transverse stability as load-bearing skeleton, conforms to health indicators, and has the characteristics of non-toxic, odorless, non-deformable, lightweight and durable.

SIR(硅橡胶):通式xSiO2·yH2O

SIR (Silicone Rubber): General xSiO 2.yH 2

硅橡胶是由二甲基硅氧烷与其他有机硅单体聚合而成的线型高分子弹性体,具有很好的耐热性,外表具有防粘作用。

Silicone rubber is a linear polymer elastomer which is polymerized by dimethylsiloxane and other organosilicon monomers. It has good heat resistance and anti-sticking effect.

SIR食品级保送带,无毒无味,外表霎时耐温可达-100℃~+250℃,可保送粘性大的面团、果糖、巧克力酱等。

SIR food-grade delivery belt, non-toxic and tasteless, instant appearance temperature resistance up to - 100 ~250 C, can deliver sticky dough, fructose, chocolate sauce and so on.

PTFE(特氟龙):通式:(C2F4)n

PTFE (Teflon): General formula: (C2F4) n

特氟龙,商标名Teflon?,依据音译又称为特氟龙、铁氟龙、铁富龙、特富龙、特氟隆等,外表具有抗酸碱、耐高温(-70℃~+260℃)、抗湿性、耐磨损等特性。

Teflon, the trademark Teflon?, according to transliteration also known as Teflon, Teflon, Teflon, Teflon, Teflon, Teflon, Teflon, etc., has the appearance of acid and alkali resistance, high temperature (-70 ~260 C), moisture resistance, wear resistance and other characteristics.

PTFE食品级保送带采用优质进口玻璃纤维为编织资料,停止平纹编织或特殊编织成高级玻纤布基材,再采用共同的工艺技术、充沛浸泡、浸渍、涂覆进口特氟龙树脂,消费各种厚度多种超宽的特氟龙耐高温漆布。

PTFE food-grade delivery belt uses high-quality imported glass fiber as weaving material, stops plain weaving or special weaving into high-grade glass fiber cloth base material, and then uses common technology, abundant soaking, impregnation and coating of imported Teflon resin, consuming a variety of ultra-wide Teflon high-temperature resistant lacquer cloth of various thicknesses.

This article is from: Food-grade conveyor belt more content please click: https://www.huafengxiangsu.com, we will provide you with a satisfactory service to ask questions, welcome your call!