一、查

First, check

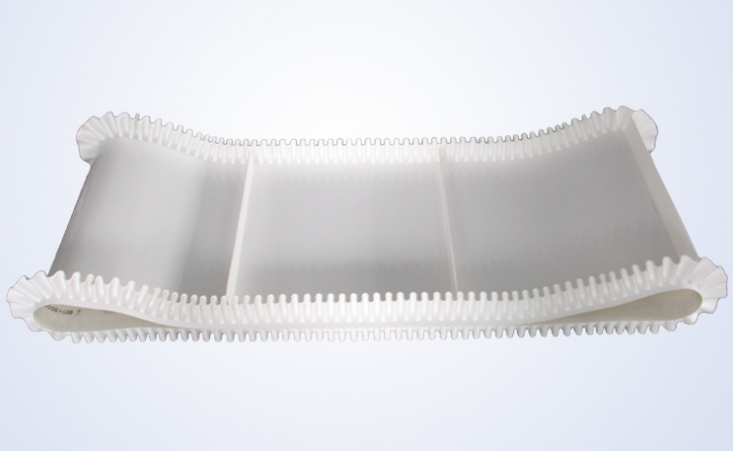

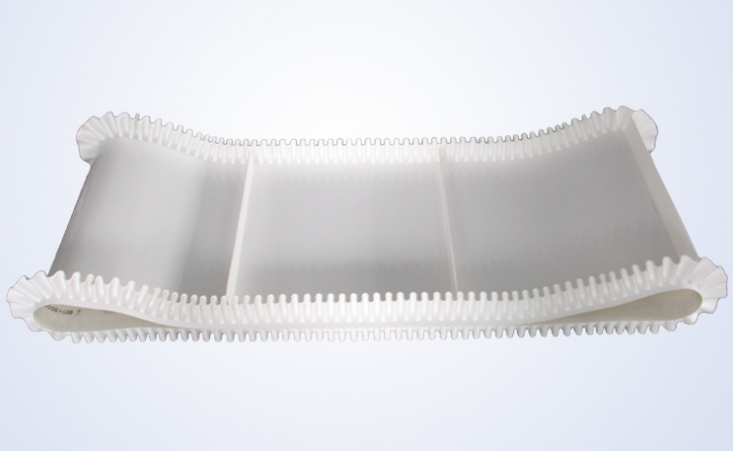

关于设备突发毛病或者人员不合理操作后,大倾角挡边带难免会呈现一些损伤,一朝一夕就会呈现断裂等状况,这步查,首先,就是要先什么缘由招致了保送带的损伤,是设备问题?还是工况问题?还是保管不当?扫除外在毛病后,再检查大倾角挡边带哪里损坏,以此来选择部分改换还是全面改换。假如是产品运用寿命到了,精诚倡议大家全部改换。

With regard to the equipment breakdown or personnel unreasonable operation, the large inclined sideband will inevitably present some damage, and it will break overnight. The first step is to investigate, first of all, what causes the damage of the belt, the equipment problem or the working condition problem? Or improper storage? After cleaning out the external defects, check where the damage of the large inclined sideband is. In order to choose the partial or comprehensive replacement. If the service life of the product is reached, we sincerely recommend that you all change it.

二、取

Two.

取就是取下保送带,这里要留意的是先切断电源,这是维护产品设备和人身平安的主要前提,切不可马虎遗忘,在断电后,先取下防护罩,将马达的装配螺栓拧松,然后挪动马达使得保送带变的松弛,就能够取下保送带了。

Take off is to take off the delivery belt, here we should pay attention to cutting off the power supply, which is the most important premise to maintain product equipment and personal safety, must not be forgotten carelessly, after power failure, first take off the protective cover, the assembly bolt of the motor is screwed loose, and then move the motor to make the delivery belt relaxed, you can take off the delivery belt.

三、装

Three, loading

再装之前,精诚倡议好再对设备检查一遍,传动安装、轴套、防跑偏安装等都需求检查,无误后就能够停止大倾角保送带的装置了,只需求依照正确位置装置即可,装置时不要撬保送带或者用很大的外力塞,会招致保送带变形,也存在磨损的隐患。

Before reinstallation, sincere proposal is best to check the equipment again. Drive installation, sleeve, anti-running deviation installation and so on all need to be inspected. If there is no mistake, we can stop the device of high inclination belt. Only the device according to the correct position is required. When installing the device, do not pry the belt or use a large external force plug, it will cause deformation of the belt, and there is also a hidden danger of wear and tear.

四、紧

Four, tight

装置完成后,拧紧马达的装配螺栓,纠正扭矩,能否拧紧是保送带改换后能否与设备正常配合和运转的重要条件。

After the installation is completed, tightening the assembly bolt of the motor, correcting the torque and tightening are the important conditions for the normal cooperation and operation of the conveyor belt after the replacement.

五、测

Five, measurement

有些企业在装置完成后,立即开机,高速运转设备,这样很容易招致保送带的损伤,测试是为了确保改换无误,详细的操作就是,先运用低速运转,察看和听能否有异常或者摩擦的噪音,确保没有问题后,再转到高速正常运用即可,置信企业也不急于这一点时间吧。

Some enterprises start up immediately after the completion of the device, high-speed running equipment, so it is easy to cause damage to the delivery belt. The test is to ensure that the replacement is correct. The detailed operation is to use low-speed operation first, to see and listen to abnormal or frictional noise, to ensure that there is no problem, and then switch to high-speed normal operation. Believe that the enterprise is not in a hurry at this time. 。

Thank you for your reading. For more information and questions, please click: https://www.huafengxiangsu.com. We will continue to work hard to serve you. Thank you for your support!